Preventive Maintenance Batching - PM Scheduling the Efficient Way

Does your normal preventive maintenance routine have your team doing laps around the facility? Going from area to area inspecting one thing then going around again to inspect another. Seems like a waste of time doesn't it? You might need to take a look at how you're scheduling PM's. PM batching is a more efficient way of scheduling your work because it groups together like inspections by location and recurrence instead of equipment type, reducing the need to burn laps like Jimmie Johnson at the Daytona 500.

Try scheduling daily, weekly, monthly, and annual PM inspections for each location denomination that is important to your workflow (rooms, departments, etc.). Doing your preventive maintenance this way allows you to get all of the inspections that need to be done for that location, at that time, completed in one visit.

PM batching will save your maintenance team time that normally would be wasted on unnecessary travel and minimizes the chances of getting distracted by co-workers while they are trying to get from job to job.

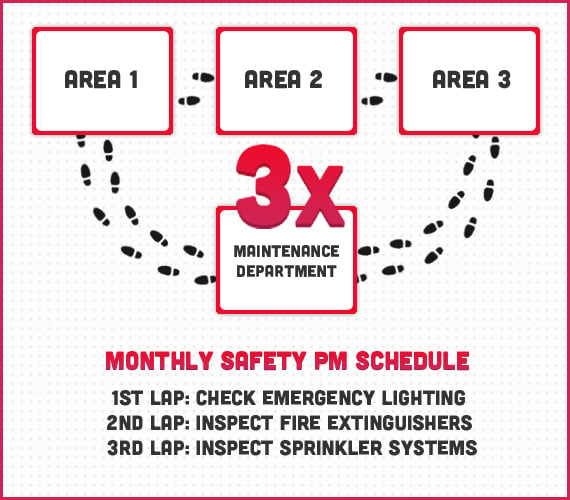

Here's an example of the old way of scheduling PM's..

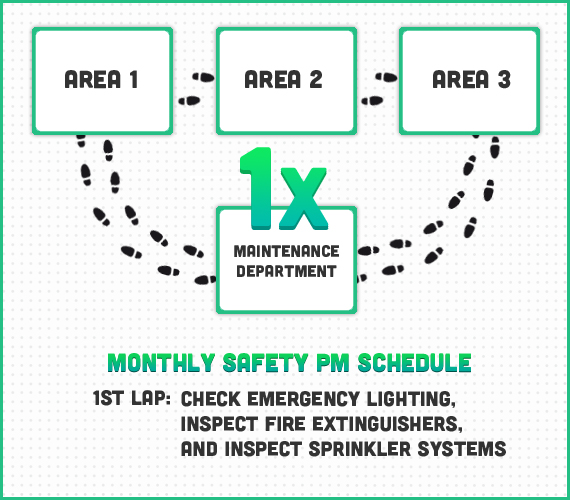

Here is an example of the new way using PM batching..

In these examples, you can see that PM batching reduced the number of laps the maintenance technician had to do from three; one for each piece of equipment, to one, where all three inspections are completed during each area's initial visit.

Que Centre's CMMS software can be set up to schedule preventive maintenance based on locations, where all assets at a particular location will show up in the work order based on whether it is a daily, weekly, monthly, or annual PM work order. Your PM checklists and procedures can also be attached to work orders and printed, making the batching process even easier.

Click below to learn more..

Ryan Noble

Ryan is Q Ware's Marketing Specialist.